Have you ever wondered about the differences between zinc and aluminum alloy die castings? Or perhaps you’re trying to decide which material is best suited for your manufacturing needs? In this comprehensive guide, we’ll explore the intricacies of die casting and help you understand the key differences between zinc and aluminum alloys.

First, let’s dive into the world of die casting, a process that enables the production of complex metal parts with high precision and excellent surface finishes. By understanding the techniques and materials used in die casting, you’ll be better equipped to make informed decisions for your manufacturing projects. So let’s get started!

What is die casting, and why should I care?

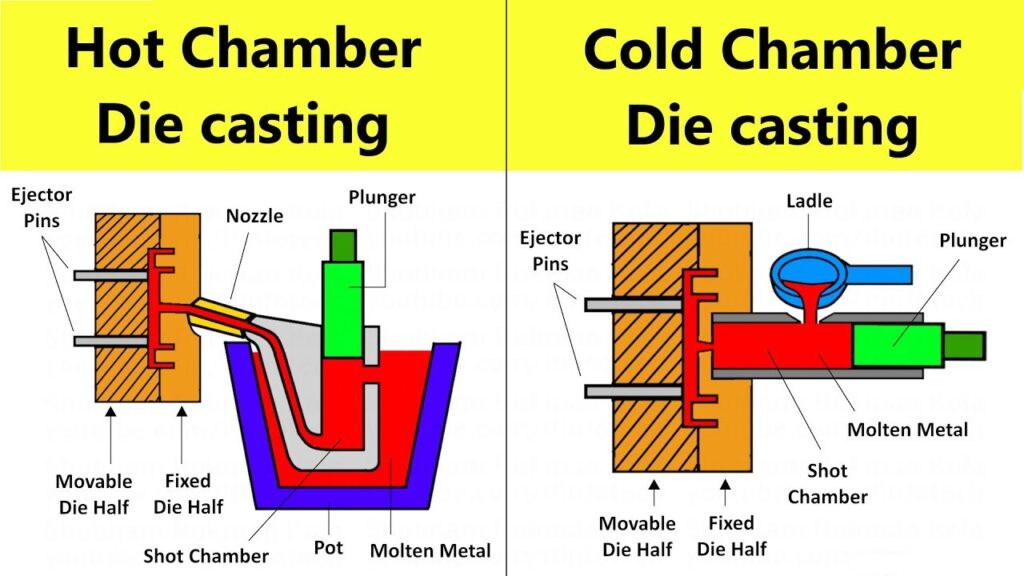

Die casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity. The process allows for the production of complex, high-quality parts with a high degree of precision and repeatability. Two main types of die casting machines are used in the industry: hot chamber and cold chamber die casting machines. The choice between these two methods depends on the metal alloy used and the desired production volume.

What are the key differences between zinc and aluminum alloys?

Both zinc and aluminum alloys have unique characteristics that make them suitable for different applications. Here’s a quick comparison of their properties:

- Zinc alloys are known for their excellent strength, rigidity, and dimensional stability. They have a lower melting point than aluminum alloys, making them suitable for hot chamber die casting. Zinc alloys also offer excellent surface finishing options, such as plating and painting, and are more cost-effective than aluminum alloys. Resources

- Aluminum alloys are lightweight, corrosion-resistant, and have good thermal and electrical conductivity. They have a higher melting point than zinc alloys, requiring cold chamber die casting machines for processing. Aluminum alloys are more environmentally friendly due to their recyclability and are commonly used in applications requiring heat dissipation or lightweight components. Resources

How do I choose the right alloy for my project?

The choice between zinc and aluminum alloys depends on several factors:

- Material properties: Consider the specific requirements of your project and compare the properties of zinc and aluminum alloys to determine the best fit. Resources

- Design complexity: If your design requires intricate shapes and high precision, zinc alloy die casting might be the better choice. For parts requiring better heat and electrical conductivity, aluminum alloy die casting is more suitable.

- Budget considerations: While zinc alloy die casting is generally more cost-effective, it’s essential to consider the long-term benefits and potential savings associated with aluminum’s lighter weight and recyclability.

- Production volume: Evaluate your production volume requirements to determine the most efficient die casting process for your project. Hot chamber die casting is ideal for large-scale production of low-melting-point metals like zinc, while cold chamber die casting is more suitable for smaller-scale production of high-melting-point metals like aluminum.

What sets Zenhite Hardware apart from the competition?

At Zenhite Hardware, we specialize in manufacturing and distributing high-quality hardware equipment, including machine parts, metal fittings, and pressure gauges. Our commitment to quality control, technical support, competitive pricing, and personalized service sets us apart from other hardware equipment manufacturers. We serve a wide range of clients, from appliance manufacturers to gas range factories, and export our products worldwide. Resources

Conclusion

In conclusion, understanding the differences between zinc and aluminum alloy die castings is essential for making informed decisions about your manufacturing needs. Zinc alloys are known for their strength, rigidity, and cost-effectiveness, while aluminum alloys offer lightweight, corrosion-resistant, and environmentally friendly solutions.

By considering factors such as material properties, design complexity, budget constraints, and production volume, you can select the most suitable alloy for your project. At Zenhite Hardware, we pride ourselves on our commitment to quality control, technical support, and personalized service, ensuring that you receive the best die castings for your specific needs.

If you’re still unsure about which alloy is right for your project or want to learn more about our range of hardware equipment, don’t hesitate to contact us for expert guidance and support. Our team of skilled professionals is dedicated to helping you make the best decisions for your business and ensuring the success of your manufacturing projects.